When your inventory is running low or you’re looking at a broken part in your hand, your natural reaction is to panic. After calling the manufacturer, you might learn about a long lead time, high cost, or that the part is obsolete. This is where 3D printing replacement or replicated parts makes sense. In this article, we’ll explain the use of a 3D printer in this application and break down when it is and isn’t useful.

What is a Replicated Part?

A “replicated part” is one that was cloned from the original piece. In many cases, it refers to taking a part, reverse engineering it, and creating a new version.

You’ll see this option a lot when it comes to 3D printing companies, and it’s one of the biggest selling points of working with their shop.

For example, let’s say a gear breaks on your machine. It snaps in half and you’re left with two pieces. A part replicator will take the pieces, professionally model what the original looked like, then create a perfectly scaled, identical version of the part. It’s important to understand that the part replicator is not the same company that you originally got the gear from.

Difference Between Replicated Parts and Spare Parts

The company that originally sold you the gear can offer you spare parts for sale. They have the gear as one of the items in their inventory. They have the designs, and they use a machine shop to fabricate each gear.

If you buy five gears from the manufacturer, now you have four spare parts. Alternatively, you can get five replicated parts from a 3D printer shop. Again, the key distinction is who you get the parts from.

- Spare parts: From the original manufacturer.

- Replicated parts: From a different machine shop or 3D printing shop.

Benefits of 3D Printing Replacement Parts

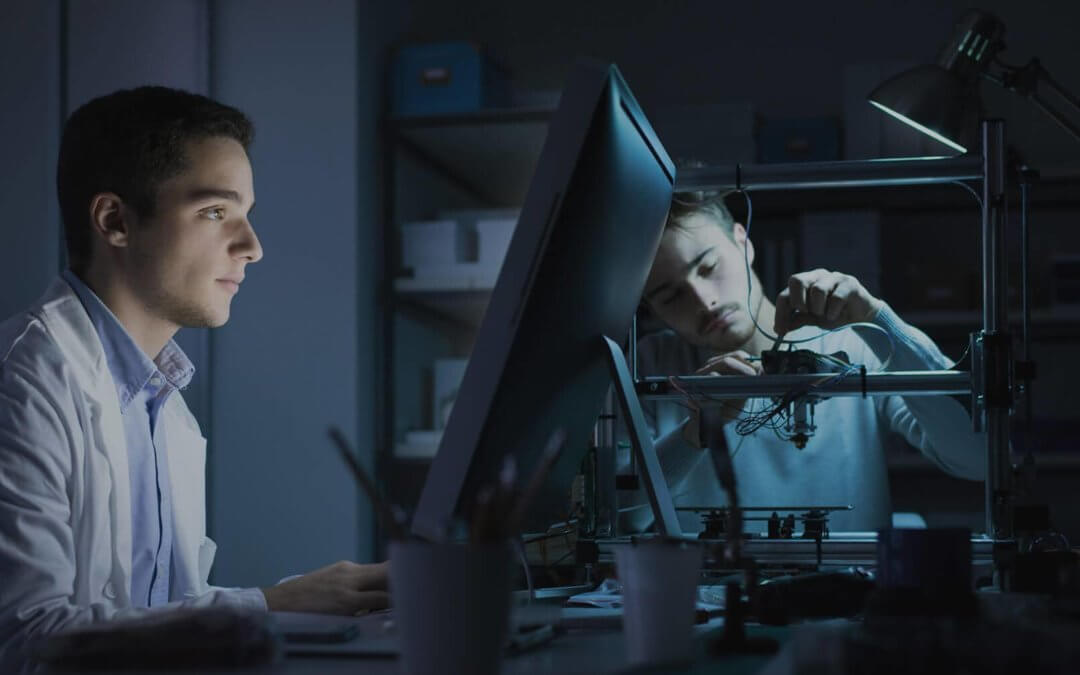

With those terms explained, let’s talk about what makes 3D printing so great for this application. As you can probably tell, we’re excited to get into the details.

Creating Obsolete or Hard-to-Find Parts

What are you supposed to do if the original manufacturer goes out of business, stops making that specific part, or just disappears? Our bet is that you can’t just shut down your machine and build a new one from scratch.

When you need a part that’s obsolete or hard to find, turn to a replacement part manufacturer. We don’t care whether or not the original manufacturer still stocks this replacement part. We’ll reverse engineer it and manufacture a new one for you. That’s the beauty of on demand manufacturing.

Upgrading and Improving the Previous Design

Other times you’re using an OEM part that seems like it’s missing something. In your mind, it would work a lot better if it had a small tweak to the design.

If you call the part manufacturer and tell them this, they’ll laugh at you and hang up. They offer the part a certain way, and you have to accept it.

If you call a replacement parts manufacturer, they’ll get to the drawing board. After we make a 3D model of the original part, we can tweak the design as much as you’d like us to. We’ll add, subtract, modify, improve, and upgrade the design.

This could result in higher production rates for you and more profits each year.

Low-Cost Option

Companies don’t build their business around making spare parts for you. A lot of companies actually treat it like a chore. They’ll upcharge you like crazy and tag on a ludicrous shipping cost so they can make it worth their while.

3D printing a replicated part is the complete opposite. This operation is really cost-effective, especially in low-run production. We can 3D print on demand the same part for a fraction of what the original spare part costs you.

Fast Turnarounds

As well as being a low-cost alternative, 3D printing also boasts really fast turnarounds. In some cases, we can have a piece reverse engineered and printed within 24 hours. Compare that to the 6-week lead time that the original manufacturer quoted you, and you’ll see why we’re so excited about 3D printing.

We can also quickly iterate a design and send over a bunch of different prototypes faster than their single replacement will hit your loading dock.

The Unique Challenges of 3D Printing a Replacement Part

There are some challenges that are unique to 3D printing a replicated part. These don’t really slow down the process, but it’s something to consider. A high-quality 3D printing facility can easily work their way through these challenges.

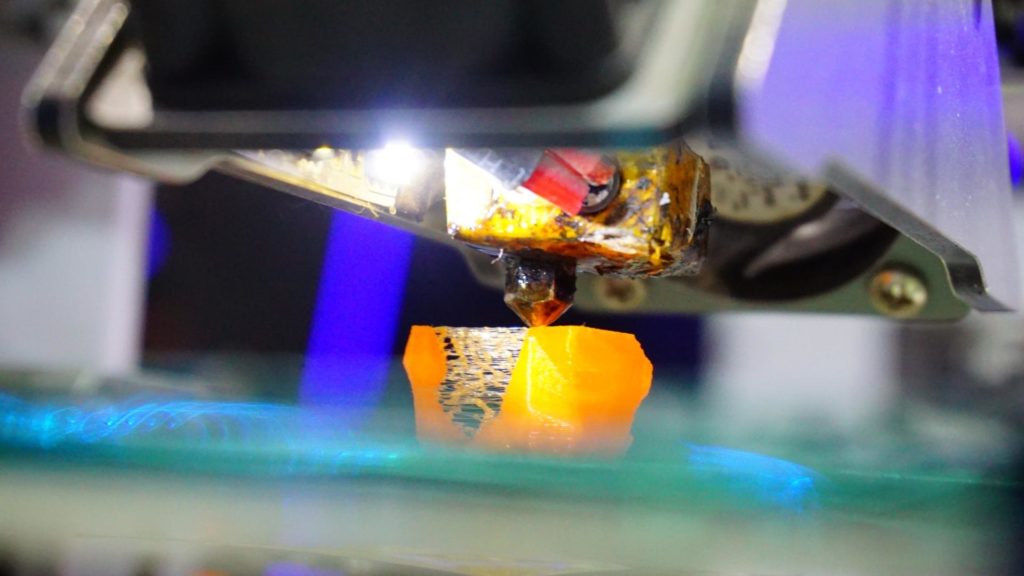

Reverse Engineering

Reverse engineering is arguably the hardest piece of making a replacement part. Measuring a part perfectly takes some time, attention to detail, and a load of experience. Once measured, the piece has to be professionally 3D modeled by an engineer.

Our in-house teams make this step look easy, but it’s admittedly harder than it seems – especially with certain intricate parts. When companies need replacements for parts that are really complicated, we happily step up to the challenge.

The original manufacturer already has a set of drawings that they can build from, so they have a head start here.

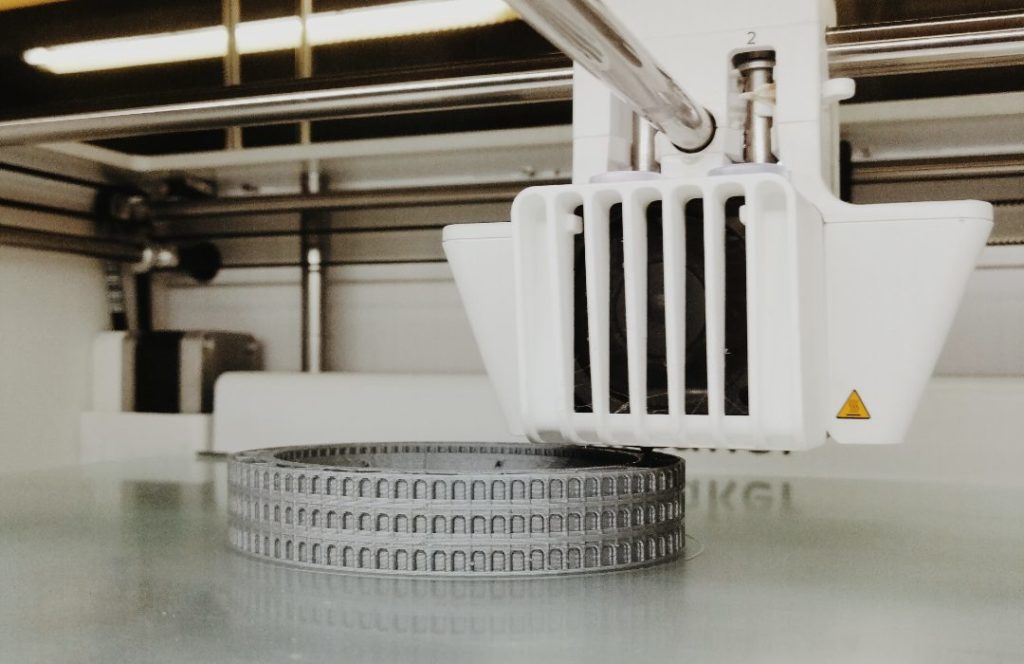

Proper Set-Up of 3D Printer

Setting up a 3D printer requires some parameters to be input. Again, this is an area where a good shop makes it look simple. Our trained techs know what parameters to adjust depending on our clients’ needs.

You could compare this to setting up a CNC mill to run the same part at the original shop.

Choosing the Right Material

Lastly, we have to get the material right. You might not know the original material, or you might want to change it. Our guys have a long history in the mechanics of material selection. We’ll be able to suggest the right material for the job and get it loaded into our printer. This applies to any type of plastic you can think of and a wide range of metals.

The Cost-Effective Nature of 3D Printing Replacement Parts

A topic that always comes up about 3D printing is how cost-effective it is in low-run production. Replacement parts by their very nature are low-run, so this is where 3D printing really shines.

The material and operation costs of a 3D printer are almost negligible. On top of that, you don’t need to pay for a machinist to run the parts. If you want a handful of spares, then often 3D printing will be orders of magnitude less expensive than traditional machining.

The Right and Wrong Times to 3D Print a Replacement Part

If you’re not familiar with 3D printing, here are the right and wrong times to consider it. This will help you make your decision when it comes to getting 3D printed replacement parts.

Right: Obsolete Parts

If the manufacturer no longer makes the part, you don’t have any other options. You can try to find one online, but who can guarantee the legitimacy of it? The best method is to have the obsolete part 3D printed and sent to your office.

Right: Unique Materials or Multiple Materials

3D printing can take a single 3D model and print units in a range of different materials. We can print metal replacement parts easily for you.

This opens the door for customizing a part. We can tailor it to hit the performance expectations you have while still withholding the same tolerances and functionality.

Right: Shipping/Pricing Concern with Manufacturer

You should never overpay for a replacement or spare part. If the manufacturer quoted you an outrageous number for shipping and manufacturing a part, reach out to us.

Our quotes are always fair because 3D printing is a low-cost option. Shipping is typically easier too, since there are fewer moving parts, and we manufacture all of our parts in America.

Wrong: OEM-Certification Required

If there’s any requirement that replacement parts need to be OEM-certified, then 3D printing might not be the right option. As a manufacturer, you might have some stipulation that forces you to use OEM-certified replacement parts.

However, there are exceptions to this rule. For example, we’ve worked directly with OEM part manufacturers who needed to make legacy product lines. They worked directly with us for their OEM-certified parts because it was quicker and less expensive than buying new tooling to create inventory.

Wrong: High-Production Runs

In general, 3D printing isn’t the favored manufacturing process for high-production runs. If your operation makes single-use, disposable units, you might want to look into processes like injection molding or CNC machining.

We’ve also had experience being the exception to this rule. We’ve had manufacturers work with us because the upfront cost of starting a production line is more expensive than having us 3D print the units. For example, some of the OEM part manufacturers we described earlier routinely order thousands of units from us. It saves them time and money in the long run. For obsolete parts, 3D printing high-production runs might be more cost-effective.

Making the Most of 3D Printed Parts

3D printing a replicated part can save you money, time, and headaches in the future. There’s no need to go back and forth with a manufacturer who’s unwilling to work with you, charging too much, or not offering replacement parts due to them being obsolete. If you want the best experience getting your replacement parts, you can trust us at 3D Printed Parts. Contact us today. We have an online form that you can fill out that will help us get you the help you need.

Recent Comments