3D Printing Materials

At 3D Printed Parts, we pride ourselves on having the knowledge and experience to know what 3D printing materials will be best suited for your parts and projects. Below you’ll find a list of preferred additive manufacturing materials that we offer when it comes to creating high-quality, sustainable parts for every application.

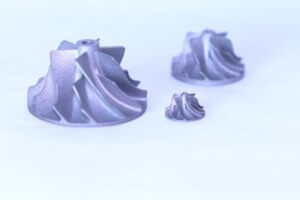

Metals

Aluminum Alloys

Aluminum Alloys are among the most popular materials being researched for new additive manufacturing applications. A lightweight and reasonably strong material, in the aerospace and automotive industry, they are used for their lightweight.

Both innovative approaches to mold design and specific heat exchanger applications make use of the high thermal conductivity of these alloys. With Laser Powder Bed Fusion, exceptionally thin walls can be produced, opening up new opportunities for functional design.

|

3D Print Technologies |

Pros |

Alloys |

|

Laser Powder Bed Fusion Direct Metal Laser Melting Direct Metal Printing |

|

Pricing: $$

Cobalt Chrome

Cobalt-chromium-molybdenum alloys are known for their high strength and hardness. They retain these properties even at elevated temperatures. In addition, they spontaneously form a protective passive film, which makes Cobalt Chrome both corrosion-resistant and biocompatible.

These benefits make Cobalt Chrome the ideal material for medical tools, devices, molds and dies, industrial, high-wear applications, and parts requiring high strength at elevated temperatures.

|

3D Print Technologies |

Pros |

Alloys |

|

Laser Powder Bed Fusion Direct Metal Laser Melting Direct Metal Printing |

|

|

Pricing $$$

Nickel Alloys (Inconel)

Nickel alloys are known for their combination of high strength and excellent corrosion resistance. Nickel alloys are the ideal material for industries where these two strengths need to come together: chemical, marine, aerospace and nuclear industries.

Products made with Nickel Alloys include reaction vessels, tubing, heat exchangers, valves, engine exhaust systems, turbine seals, propeller blades, submarine fittings, propulsion motors, reactor core and control-rod components in nuclear water reactors.

|

3D Print Technologies |

Pros |

Alloys |

|

Laser Powder Bed Fusion Direct Metal Laser Melting Direct Metal Printing |

|

Pricing: $$$

Stainless Steel

Stainless Steel has excellent corrosion resistance, strong mechanical properties and excellent toughness. These alloys are sterilizable, machinable and heat treatable. They are used in everything in general metalworking, automotive, marine and aerospace applications, as well as medical devices and surgical instruments. They are suitable for structural components in extreme environments.

|

3D Print Technologies |

Pros |

Alloys |

|

Laser Powder Bed Fusion Direct Metal Laser Melting Direct Metal Printing |

|

Pricing: $$

Maraging Steel (1.2709)

A genuine tool steel that is easily heat-treatable in a simple age-hardening process resulting in excellent hardness and strength, Maraging Steel has good wear resistance. In regards to post-processing, the material shows good weldability and machinability.

Maraging Steel is ideal for innovative tool and mold designs including conformal cooling channels for injection molding, die casting and extrusion. The material is also used for high-performance aerospace, automotive and other industrial applications that require high strength and wear resistance.

|

3D Print Technologies |

Pros |

Alloys |

|

Laser Powder Bed Fusion Direct Metal Laser Melting Direct Metal Printing |

|

Pricing: $$

Titanium Alloys

Titanium is commonly used for lightweight and high-strength components such as aerospace and motorsports applications. Because of its excellent biocompatibility, it is also very well suited for medical implants, tools, and devices as well as dental prostheses.

Titanium is the ideal material for lightweight, high-strength components as required for a broad scope of parts in aerospace, sports, and marine products. Its high strength and biocompatibility make it the material of choice for medical tools, implants, and devices.

|

3D Print Technologies |

Pros |

Alloys |

|

Laser Powder Bed Fusion Direct Metal Laser Melting Direct Metal Printing |

|

Pricing: $$$-$$$$

Non – Metal 3D Printing Materials

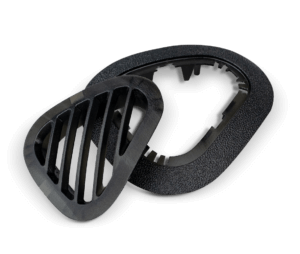

Polypropylene-Like Plastics

Flexible, high impact-resistant material for extremely durable parts with the look and feel of production polypropylene. Polypropylene-like plastics are great for functional prototypes, enclosures, and assemblies, as well as short-run production parts.

With their fatigue-resistant characteristics, these materials provide outstanding flexibility and accuracy, enabling many new additive manufacturing applications.

|

3D Print Technologies |

Pros |

Materials |

|

Figure 4 Stereolithography Selective Laser Sintering |

|

Pricing: $-$$

ABS-Like Plastics

Strong plastics simulating injection-molded ABS, for fast high-performance prototyping and production applications where stability is critical and mechanical properties fit.

With production-grade stability, mechanical properties, color and opacity, this material provides high precision, smooth surface finish and exceptional sidewall quality with minimal finishing.

|

3D Print Technologies |

Pros |

Materials |

|

Figure 4 Multi Jet Printing |

|

Pricing: $$

Nylon

A durable thermoplastic with balanced mechanical properties and fine-feature surface resolution. For real-world functional testing and low to mid-volume production runs. Capable of meeting UPS Class VI.

|

3D Print Technologies |

Pros |

Materials |

|

Selective Laser Sintering |

|

Pricing: $-$$

Transparent Plastics

Utilized in a variety of demanding applications, transparent materials simulate the properties and appearance of Polycarbonate and ABS. This unique combination of clarity, material properties and processing speed make these materials a high performing and cost-effective choice for aesthetic and functional prototypes.

Transparent plastics are commonly used to improve product development efficiency of consumer goods, automotive, aerospace and medical components.

|

3D Print Technologies |

Pros |

Materials |

|

Stereolithography Multi Jet Printing |

|

Pricing: $-$$

Rubber-Like 3D Printing Materials

Perfect for design verification of gaskets, hoses, tubing and seals. These materials are even used in industrial applications as spacers, masks and vibration dampening components. Great for soft-touch applications such as end effectors and grips.

|

3D Print Technologies |

Pros |

Materials |

|

Figure 4 |

|

Pricing: $-$$

Custom 3D Print Quotes

"*" indicates required fields

Recent Comments